Media Focus | Ten Years of Evolution in Electric Trailers: Who Will Define the Next Generation of Transportation Equipment?

May 20,2025

Against the backdrop of the global ‘dual carbon’ strategy being deeply implemented, the transportation industry, as one of the key sectors contributing to carbon emissions, is facing an urgent need for green transformation. As the main vehicle type for long-distance road transport, the initial focus of emission reduction efforts for semi-trailer truck trains was on the tractor unit (main vehicle). However, with the rapid development of new energy technologies, commercial vehicle manufacturers are now extending their innovative focus to the trailer sector to continuously improve transport efficiency and reduce carbon emissions.

The transition to new energy heavy-duty trucks is accelerating, and the electric trailer industry has already attracted dual attention from both policy and market perspectives. As early as 2024, the National Automobile Standardisation Technical Committee of China convened the ‘Electric Trailer Standard Demand Research Project Kick-off Meeting,’ marking the entry of China's electric trailer technical specification system into a substantive construction phase. The European Union has also set a clear timeline for reducing trailer carbon emissions, requiring semi-trailer products to achieve a 10% reduction in carbon emissions by 2030.

Under the pressure of increasingly stringent regulations, the global trailer industry is accelerating the development of next-generation environmental technology solutions—electric trailers have become a key breakthrough point for industry transformation.

01 The Origin and Early Exploration of Electric Trailers

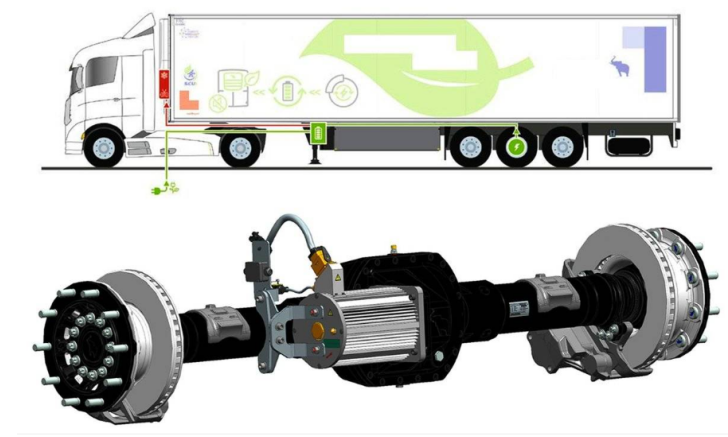

The first commercial demonstration of electric drive axle technology for trailers can be traced back to the 2018 Hannover Commercial Vehicle Show. At that time, SAF-HOLLAND, a world-renowned trailer axle manufacturer, exhibited its newly developed electric drive axle product for trailers, marking the official entry of this technology into the market.

The SAF TRAKr electric drive axle was first exhibited at the 2018 IAA.

Driven by this technological wave, leading international truck suppliers and trailer manufacturers, including ZF, WABCO, and Schmitz Cargobull, have increased their R&D investments and actively expanded into the field of trailer electric drive axle technology.

As the seed of electric trailer development, the mainstream technology route focuses on passive energy recovery systems. This technology involves installing motors and battery packs on the trailer axle to convert kinetic energy generated during braking into electrical energy for storage, thereby achieving energy recovery and reuse.

At this stage, trailer electric drive axle technology is primarily generator-type, such as Schmitz Cargobull's mass-produced Rotos axle and the 17kW electric drive axle from American company Carrier.

Kgel Cool –PurFerro series refrigerated trailers with energy recovery systems

However, the technology at this stage still has obvious limitations: first, energy recovery efficiency is highly dependent on road conditions, and the system can only achieve limited energy replenishment; second, early systems are costly, and the increased weight of batteries significantly reduces payload; finally, economic indicators are difficult to meet market demand. These technical pain points have prompted the industry to explore more advanced solutions.

The core components of Schmitz Cargobull's electric refrigerated semi-trailer are the power generation axle, battery pack and pure electric refrigeration unit, which enable energy recovery.

02 Development and Challenges of Independent Electric Trailers

While recovering energy, to better provide power support for trailers, after 2022, global electric trailer technology entered a breakthrough development phase, with mainstream technology shifting from power generation-type to trailer independent drive-type.

In October 2021, European commercial vehicle manufacturing giant Krone partnered with Trailer Dynamics to jointly launch a professional electric trailer (e-Trailer) solution, marking the first time the concept of electric trailers was introduced. Brazilian company Suspensys also collaborated with Brazilian trailer giant Randon to launch an independently driven electric trailer, which has already begun small-scale production.

Krone and Trailer Dynamics launch electric trailer e-Trailer

The independent electric trailer retains its braking energy recovery function while integrating a high-power drive motor and a large-capacity power battery pack, thereby granting the trailer independent power output capabilities. This marks a technological leap from an ‘energy recovery device’ to an ‘intelligent drive unit.’

Domestic companies are also actively exploring this field. A certain trailer manufacturer has deployed battery packs, electric drive axles, and BMU controllers on semi-trailer chassis using modular integration technology, establishing a composite power system with auxiliary drive and energy recovery functions.

On 14 May 2024, the European Union amended the definition of electric trailers in Directive 2018/858. The amended definition of ‘electric trailer’ refers to any trailer that can assist the vehicle combination in propulsion using its own electric power system, and it cannot be used on public roads if it is not actively towed by a vehicle.

This means that trailer electric drive axle technology that merely provides energy storage (such as the power-generating type mentioned above) cannot be classified as an electric trailer, while trailer electric drive axle technology with independent power output capability (such as the trailer-independent type) can be classified as an electric trailer.

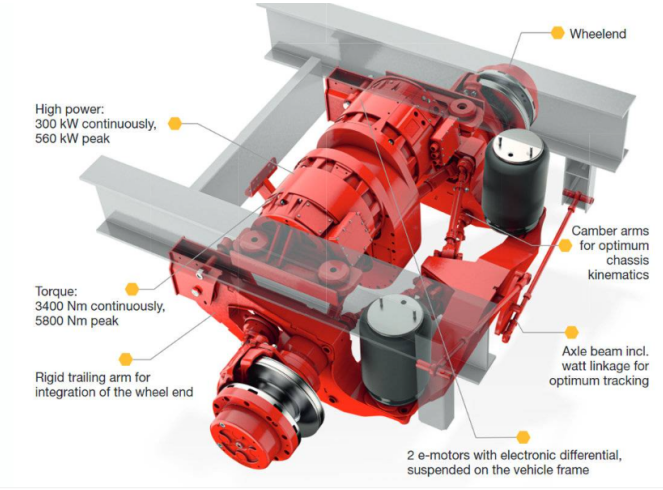

As a result, energy recovery plus power assistance has become a key focus for the global electric trailer industry, and electric trailers are now experiencing a new wave of research and development. Take the 2024 Hannover Motor Show as an example: ZF's electric concept semi-trailer under the new brand name ‘TrailTrax,’ KRONE's eCOOL LINER electric semi-trailer, and Trailer Dynamics' eCool Trailer model electric semi-trailer all garnered significant attention from attendees.

Trailer Dynamics' independent electric drive axle structure for trailers launched at the 2024 IAA

Unlike energy recovery types, independent electric trailers have achieved technological breakthroughs in three areas: first, drive system innovation, using wheel-side motors or central motor drive solutions; second, battery technology upgrades, with increased energy density significantly enhancing range; and third, the development of intelligent control systems, enabling autonomous regulation of trailer power. These technological advancements have transformed electric trailers from mere energy recovery devices into intelligent transport units with auxiliary drive capabilities.

03 Integrated Main-Trailer Collaborative Solution

Despite ongoing technological advancements, independent electric trailers still face numerous challenges in practical applications.

The most pressing issue is the challenge of collaborative control. Since the power systems of the tractor and trailer are independent, achieving perfect coordination during acceleration, braking, and other operating conditions is difficult, which not only affects driving comfort but may also pose safety risks. Especially with the continuous development of intelligent connected vehicle technology, the demand for integrated tractor-trailer collaboration in electric trailers has become increasingly evident, and integrated tractor-trailer collaboration electric trailers have emerged as a new trend.

The integrated coordination technology for electric trailers not only retains the technical features of independent electric trailers but also establishes an intelligent interconnection mechanism between the main vehicle and trailer. When the driver operates the tractor, their driving intentions are analysed by the integrated intelligent control system and coordinated actions are assigned to the main vehicle and trailer. Control commands are then transmitted in real-time to the trailer, enabling precise synchronised responses between the main vehicle and trailer.

After electric trailers and main vehicles undergo integrated co-development, their power systems no longer operate independently. In scenarios such as acceleration and braking, they achieve intelligent interconnection mechanisms and rapid response. This collaborative control model breaks through the limitations of traditional main-trailer systems operating independently, significantly enhancing the vehicle's overall manoeuvrability, safety, and energy efficiency.

Currently, European companies have taken the lead in exploration—parts giants like ZF and Swedish autonomous driving company Einride are experimenting with more information exchange between trailers and tractor units on next-generation electric trailer prototypes, beginning new explorations into the concept of main-trailer integration.

However, true head-to-trailer integration requires breaking through corporate boundaries to achieve deep integration of the entire vehicle system, which places higher demands on supply chain collaboration.

Therefore, in response to industry pain points, CIMC Vehicles (301039.SZ) has closely collaborated with strategic automotive partners to establish a technical innovation platform for pure electric head-to-trailer trains (EV-RT). Its collaboration with Shaanxi Automobile Group has become an industry benchmark, pioneering the ‘tractor-trailer integrated’ development model, enabling synchronised design of the tractor and trailer. Both parties have adopted the ‘good tractor, good trailer’ business model as the operational foundation, with technological focus on systemic innovations such as ‘tractor-trailer collaborative control’ and ‘tractor-trailer collaborative braking energy recovery,’ continuously driving technical breakthroughs and application scenario expansions for pure electric tractor-trailer trains.

Zhongji Vehicles' pure electric articulated truck (EV-RT)

Building on this breakthrough, Zhongji Vehicles has rapidly advanced the commercialisation of its products. In 2024, Zhongji Vehicles launched its first pure electric articulated truck, the J-RT1.0 mixer truck, into the market, with a batch deployed for operations in the Xi'an market. The primary application scenarios are port transportation and concrete logistics. The articulated truck offers reliable manoeuvrability and achieves energy savings of up to 37.7%.

In 2025, CIMC Vehicles will further develop the all-electric articulated dump truck (EV-RT2.0-7A dump truck) and the all-electric articulated mixer truck (EV-RT 2.0-mixer truck); in 2026, it plans to launch intelligent all-electric articulated refrigerated trucks and intelligent all-electric automotive parts logistics trucks.

In addition to continuously iterating the design and manufacturing of pure electric articulated trains, CIMC Vehicles is actively building market entry channels. This year, the company plans to invest in a pure electric articulated train assembly base in Luzhou, while also investing in four pure electric articulated train stores in Sichuan, Chongqing, Yunnan, and Guizhou, focusing on sales and after-sales services for pure electric articulated trains. These stores, together with the Luzhou assembly base, form the marketing network for pure electric semi-trailers in Southwest China, facilitating communication between users, operators, manufacturers, and local government authorities responsible for vehicle registration, while also providing vehicle financing and used vehicle transaction services.

As the product portfolio of pure electric semi-trailers continues to expand and the sales network is further developed, customised solutions tailored for specific scenarios such as port logistics, urban delivery, and construction projects will emerge, positioning CIMC Vehicles to capitalise on the vast market potential of electric semi-trailers.

According to data from Special Purpose Vehicles, China's new energy tractor market experienced explosive growth in 2024, with annual sales reaching 55,800 units and market penetration rising to 17.43%, nearly tripling from 5.87% in 2023. This data clearly indicates that new energy tractors have entered a phase of large-scale application. Against this backdrop, semi-trailers equipped with integrated main-trailer coordination technology will inevitably welcome a golden opportunity for synchronous development. Over the next 5 to 10 years, they are likely to experience market explosions across various application scenarios.

04 Conclusion

Li Guiping, Chairman and CEO of CIMC Vehicles, has publicly stated: ‘In our third entrepreneurial endeavour, we aim to become pioneers, builders, and operators of the entire value chain for pure electric semi-trailers.’ The integrated main-trailer synergy technology solution proposed by CIMC Vehicles precisely captures the strategic window of opportunity for the new energy transformation of commercial vehicles, leveraging systematic technological innovation to create globally competitive new energy transportation equipment solutions.

The integrated main-trailer collaborative technology not only fills the technical gap in China's electric trailer system integration field but more importantly, it will drive China's transformation from a technology follower to a standard-setter in the electric trailer sector.

This is not only a competition in technological innovation but also a crucial opportunity to drive the transformation and upgrading of the entire commercial vehicle industry.

Contact Us

E-mail:

Whatsapp:

Address:

West Section of Xuesong Road, Zhumadian City, Henan Province, China

News Update